Contents

Certified electricians carry out a range of electrical tests when measuring voltage, current, impedance, electrical continuity and other parameters. They use several types of electrical test equipment to ensure that wiring, electrical components and appliances are in working order and to diagnose any faults.

The scope of equipment used includes basic and inexpensive testers or complex testers used in specific cases. Some will be handy to have around the home in detecting simple electrical faults, while other gear is more suited to commercial and industrial premises with high loads. In addition, you’ll find electrical test equipment that can be used in more than one scenario and perform a variety of tests.

Voltage Meters

Voltage meters are used to measure the potential difference or voltage between two points in a circuit. They’ll let you detect live wires, diagnose issues in sockets, switches and lights, find breaks in wiring and more. They’re also often the first tool electricians use when conducting major repairs to prevent electrical shock.

Non-contact voltage testers are effective ways in locating live wires. They work in wiring and devices with different voltage requirements, form low-voltage to high-voltage applications. Simple red and green lights in the unit display the presence of a live wire or a neutral/grounding wire respectively. Sound alerts also help in dimly-lit areas and probes are used in detecting voltage in sockets.

PowerPoint Testers

Powerpoint testers are simple electrical test equipment that plug in power points to determine faults with wiring, like missing or damaged wires and incorrect or reversed connections. Some also have knobs to trip RCDs and test if they are in working order. Right lights signal a fault, and green means that there are no problems with the wiring and socket.

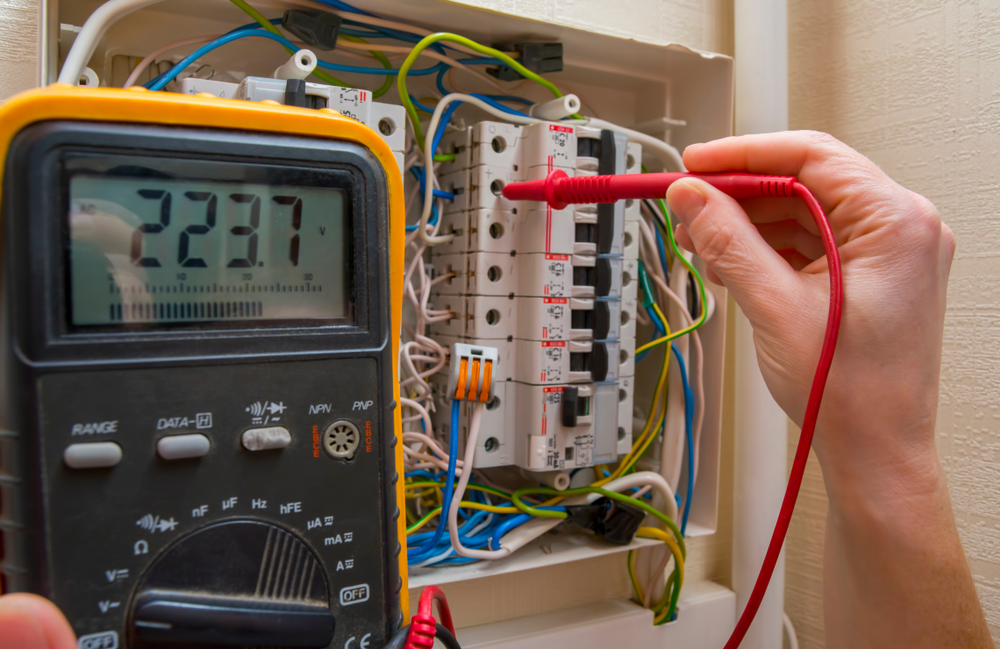

Multimeters

One of the most versatile tools in electrical tests are multimeters. They combine the function of voltage meters, ohmmeters and ammeters, to measure voltage, electrical resistance and current. Multimeters are used in a range of everyday electrical testing, like diagnosing problems with switches and power points, finding the charge levels in batteries, short circuits in wiring, damage to extension cords and more. The most accurate test results are achieved with digital multimeters that use probes to test voltage, resistance, current, continuity, capacitance and other parameters that are presented on an LCD display. A large knob is used to increase or decrease input values in wiring, circuitry and electronic components.

Multimeters are inexpensive multifunction testers found in every electrician’s toolkit, and a handy tool to have around the house. You’ll also find advanced multimeters used in high precision tasks where even the smallest change in values can signal potential electrical issues.

Clamp Meters

To measure variables in current, clamp meters are your best bet. They are more practical than multimeters in that they can measure current by clamping around live wires. This means there are no probes or cutting involved as with multimeters, so wires powering equipment or devices can be tested while still in operation. The clamp senses the magnetic field generated by a live wire, and the current value is displayed on a digital display. Besides alternating and direct current tests, clamp meters can also test voltage levels, frequency and resistance values. These are specialised test units that are commonly used in more demanding electrical applications.

Insulation Testers

These are also known as megohmmeters, or meggers for short, and are complex ohmmeters used in testing the levels of electrical resistance in insulators. They give precise data relating to the condition of such things as circuit breakers, switchgear, motor windings and transformers. Insulation meters use a high voltage direct current to measure resistance. The higher the reading the better the insulation. More advanced units have a wider range of applicable currents and increased precision so are more suited to testing industrial wiring and electrical components.

Multifunction Installation Testers

This is the do-it-all piece of testing equipment sought out by all professional electricians. It tests complex parameters like insulation resistance, continuity, low resistance, Loop and RCD measurements, Earth resistance, as well as basic functions like voltage and current. It can assess the condition of wiring, grounding, switchgear, circuit breakers, fuses, RCDs, motor windings, transformers, appliances, circuit boards and more.

Units are lightweight and display precise readings on high-resolution LCD displays with graphical overlay. With so much testing power at your disposal, expect these to cost quite a bit. You do however get a compact tester that saves space in the toolbox and money in your pocket if buying all the testers it replaces separately.

Buying Electrical Test Gear

The testers listed above are some of the most widely used in everyday cases. Some like voltmeters and multimeters are relatively simple but offer precise results when troubleshooting issues in wiring, insulation or faulty devices. These are widely available and cheap to buy. More specialised equipment, like insulation testers, multifunction installation testers, relay test sets, hipotential testers and many others are often used in high-voltage industrial testing and as such come with the appropriate price tags. For home use though you’ll be well served by basic electrical test gear to detect common issues around the house. Electrical stores stock a range of testing gear from established brands and at reasonable prices.

Comments are closed.