Contents

How many times have you told yourself that you’d like to swap your car’s factory exhaust system for something sportier? There’s just one problem with replacing your OE exhaust with an aftermarket exhausts system, though: how to be sure the replacement will actually perform better than your factory one. A lot of aftermarket exhaust manufacturers promise a world of performance – and most fall painfully short of expectations.

A premium quality exhaust system is more than just differing lengths of big pipes. It takes vehicle- and engine-specific engineering, craftsmanship, and the right choice of materials to bring the entire package together. That’s why if you’re unsure about whether the aftermarket system you’ve been dreaming about is really up to delivering what it promises, there are a few simple ways to verify its performance potential before you commit to buying.

Superior Balance is the Key to Premium Performance Exhausts

Let’s be honest: with so many aftermarket exhaust manufacturers on the market, it’s hard to know which ones are actually capable of performing as advertised. Fortunately, premium quality high performance exhaust systems are easy to identify if you know what you’re looking for.

Not surprisingly, the search for performance begins with brands whose engineering expertise you know and trust. Premier high performance exhaust manufacturers and their engineers understand that in order for an exhaust system to produce results, it has to verifiably satisfy the basics of high output exhaust design, which include:

- Ensuring the system’s scavenging is achieving its best possible exhaust gas velocity;

- Ensuring that excess exhaust gas heat remains locked in the system to help aid in scavenging; and,

- Ensuring that the detrimental effects of heat cycling are reduced as much as possible.

Top tier exhaust system suppliers know that the key to performance is superior balance that can be pointed to. And when it comes to high performance exhaust systems, they aren’t afraid to present buyers with the results of dyno tests as irrefutable proof that their systems perform.

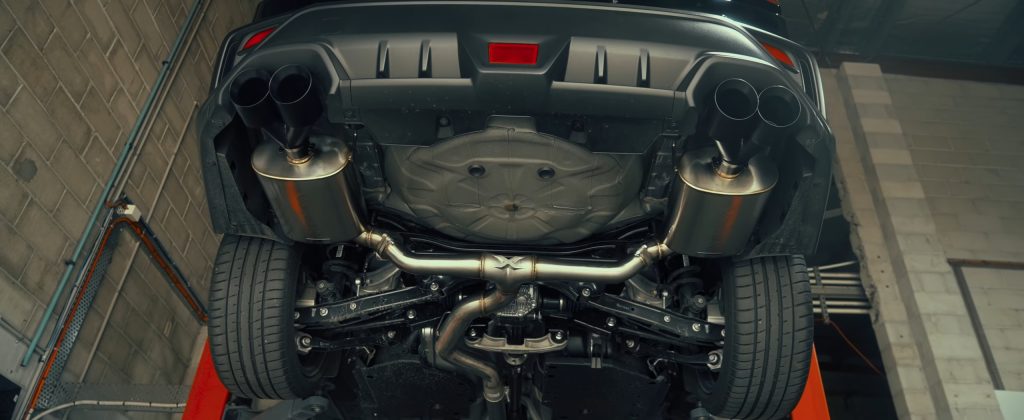

Visual Inspection Lets You See the Manufacturer Quality

Whether it’s in the precision radiusing of mandrel bent curves, or the use of TIG-welded flanges for maximum vibration resistance, craftsmanship means everything. And make no mistake: when you’re looking at a custom-built performance exhaust system constructed from components differing in lengths and diameters, the quality of the workmanship is an excellent indicator of what you can expect with regard to performance and reliability.

From header to tailpipe, visual inspections are an instant way to evaluate the level of craftsmanship that a manufacturer is putting into their exhaust systems. And as a prospective buy, you want to carefully examine a system before investing in one, especially when it comes to:

- The condition and consistency of the weld seams, fittings, and bends;

- How easily and solidly the system slips together when dry fitted; and,

- How well the system fits under your car, with or without the need for any major modifications.

And because high performance exhausts are characterised by larger pipes, now is the time to confirm that your pipe diameters are appropriately sized for your engine’s output. An aftermarket exhaust system with pipes that are too large can leave an engine drowning in its own gases, so you want to confirm with the manufacturer that your pipe diameters are optimised, and if applicable, Australian Design (ADR) compliant.

Get the Specs on Your Cat and Mufflers Up Front

With the exception of some competition and road racing exhaust setups, high flow cats, as well as low restriction mufflers and resonators are likely to be a part of your exhaust package. Both play a crucial role in how well your engine breathes. Premium performance exhaust manufacturers like xForce Exhaust Australia specialise in bespoke cat and muffler combinations ranging from 2.0“ – 4.0“.

Not surprisingly though, cats and mufflers are also subject to various degrees of regulation. That’s why in addition to dyno test results and proof of ADR compliance, your performance exhaust supplier should be able to give you the assurance that your cats are emission compliant, and mufflers are within the country’s 96db limit. As a minimum though, there are a few attributes that you’ll want to confirm about these components before purchasing them, especially if you’re looking at performance exhaust online, and they include:

- Whether your cat has a 100 or 200 cell count, both of which are conducive to higher flow;

- The type of substrate used in the cat, including the type of metal loading it has;

- The internal design and volume of the mufflers;

- The number of internal baffles the muffler has; and,

- The muffler’s inlet and outlet pipe diameters.

Ideally, if you’ve ordered a bespoke system from a high performance exhaust shop and your car is equipped with a cat and mufflers, you want to know more about it than just its advertised performance. You want to know what makes that performance possible; and across the board, this is the best way to discover what’s going to give your prime components an advantage over everyone else’s.

Materials Make the Difference in Exhaust Durability

Once you’ve addressed craftsmanship and components, you need to consider the materials used in your exhaust system. From the ultra lightweight transition metals used in top end race exhaust systems, to the austenitic alloys found in mild custom and off-road systems, an exhaust system’s design is ultimately determined by the materials it’s crafted from.

Everything, from cost to corrosion resistance, is a factor of material selection, which is why you want to know which metals your system is made from. Premium aftermarket exhausts make the best use of a balance of materials, the majority of which are:

- 304 grade stainless. Chromium-rich 304 stainless is one of the most frequently used alloys in performance exhaust systems for cars, favoured for its durability, versatility, and superbly polished finish.

- 409 grade stainless. 409 stainless is an affordable alternative to 304 stainless which, while slightly less aesthetically pleasing, possesses comparable corrosion resistance and workability.

- High strength titanium. With a price tag of up to five times more than 304 stainless, titanium is close to the pinnacle of lightweight upgrade exhaust tubing, and offers incomparable corrosion, and heat resistance.

Knowing the type of metal your exhaust system is crafted from gives you the advantage when it comes to accurately assessing a manufacturer’s claims about durability and longevity. It’s also the way to benchmark the kinds of on- and off-road conditions you’re going to want to expose your system to.

The Final Word

At the end of the day, whether it’s for the added RPMs on the top end, or for the throatier growl on the bottom, an aftermarket exhaust system can give you a new outlook on your car’s performance. When you’re choosing a system though, you want to be sure that the manufacturer’s performance is genuinely in line with what they’re promising.

That’s why when it comes to premium quality exhaust systems, you only want to buy from a manufacturer with solid performance reputation, and one who can prove their claims. It’s the best way to verify your performance potential, while protecting yourself from over-zealous performance claims.

Comments are closed.